In HPLC Solutions #122, we looked at how to measure baseline noise from a liquid chromatogram. One practical application of such measurements is to determine the noise and drift of the detector, which we’ll consider now.

First, you’ll need to establish a baseline to measure. This can be done by replacing the column with a piece of restrictor tubing, for example ≈1 m of 0.125 mm (0.005 in.) i.d. tubing. This serves to connect the autosampler and the detector and gives sufficient backpressure that the pump will function properly. Usually water is used as a mobile phase at a flow rate of 1 mL/min, but you should consult the detector manual to see if the noise is specified under other conditions. Often detector noise is reported for an empty flow cell, but that doesn’t make much sense in practical use, so determination of noise under some mobile phase condition is recommended. Also note the specifications for noise and drift as well as the wavelength at which they are determined. If you don’t see a wavelength listed, use 254 or 255 nm. Allow the detector to warm up for at least 30 min and run a baseline until it is fairly flat at maximum expansion on your computer screen. It should look something like the baseline of Figure 1. Record about 15 min of baseline.

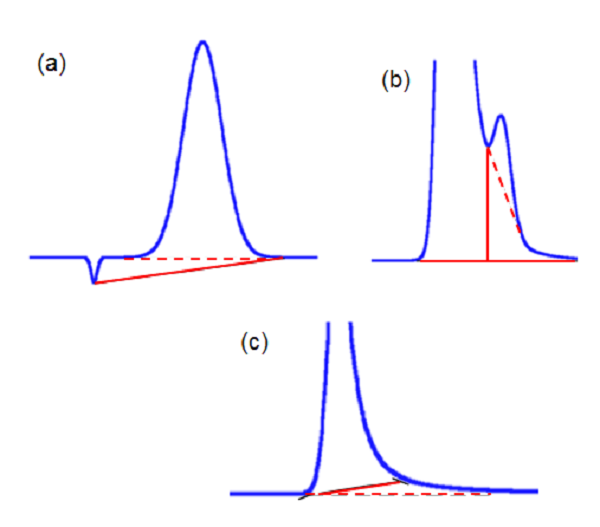

Figure 1

Figure 1

To determine noise and drift, you can print out a paper copy of the chromatogram, work directly on the computer screen, or transfer the data to some other electronic format. I find that it is convenient to do a screen capture (PrtSc) and paste it into a PowerPoint slide where I can use the various drawing tools to mark the chromatogram and make the various measurements.

Draw a line through the center of the baseline (“a” in Figure 1) and noise lines to capture the core noise (lines “b”). To determine noise, extend the noise lines to the y-axis and record the vertical spread between the lines (“c”) in whatever the display units are – microvolts (µV) in this example. Detector noise is calculated by converting this value into the specification units, typically absorbance units (AU); this detector generates 1 volt per absorbance unit. In the present example the noise is: (0.490 mV – 482 mV) x (1 V / 1000 mV) x (1 V/ AU) = 8 x 10-6 AU. The detector specification for this unit was 5 x 10-6 AU.

Similarly, calculate the drift by determining the amount of drift (“d” minus “e” in Figure 1) and noting the time. Again, convert to the units in the specifications, AU/hr in the present case: ((0.486 mV – 0.446 mV) / 15 min) x (60 min/hr) x (1 V / 1000 mV) x (1 V / AU) = 1.6 x 10-4 AU/hr. The detector specification for this detector was 2 x 10-4 AU/hr.

I like to see the detector noise and drift within ≈5 times the detector specification. This allows for non-ideal conditions in the lab compared to the ideal conditions during factory testing, as well as lamp aging and other minor allowances. The example is shown on a new detector with a new lamp, so it is well within the specifications.

This blog article series is produced in collaboration with John Dolan, best known as one of the world’s foremost HPLC troubleshooting authorities. He is also known for his research with Lloyd Snyder, which resulted in more than 100 technical publications and three books. If you have any questions about this article send them to TechTips@sepscience.com