In HPLC Solutions #109 we discussed a technique to measure noise and drift for an HPLC detector. There are several possible sources of noise in the detector, and the approach to reducing or eliminating such noise depends on the noise source. For the next few HPLC Solutions installments, we’ll look at some different sources of noise.

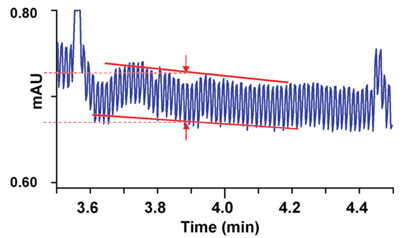

In Figure 1, you can see a greatly expanded portion of the baseline for an ultraviolet (UV) detector. Because the baseline segment is barely a minute long, it is not possible to establish the baseline drift. However, we can use the technique described in HPLC Solutions #109 to measure the noise. My measurement of the noise between the vertical arrows in ≈0.075 mAU. This converts to 7.5 x 10-5 AU. In this case, the detector specification is 8 x 10-6AU, so we are about 10 times worse than the specification. The noise alone indicates that we have a problem.

Figure 1

Figure 1

Visual inspection of the baseline also should alert us to a problem in the present case. Normally baseline noise is very random, and looks “fuzzy” when sufficiently magnified. In the present case, the baseline deviations are very regular, both in frequency and in magnitude – this is very different than the baseline noise observed under normal operation. A common source for high-frequency noise is electrical noise on the electric supply circuit. This typically has a frequency of 60 Hz (US) or 50 Hz (the rest of the world). I measure 8 deviations / 0.1 min, or 1.3 Hz in the present case, so this definitely is not “line” noise.

When it comes to isolating the source of noise as in Figure 1, you need to think about what could be influencing a very regular noise cycle, such as this. The most obvious source is the HPLC pump – a noise spike every 0.75 sec could very well correlate with the pump stroke. The simple way to check this is to double or halve the flow rate. If the frequency changes in proportion to the change, you have identified the source as the pump. A faulty check valve, worn pump seal, or broken piston are the most likely causes of the problem. Use a step-by-step isolation technique to figure out which of these is the problem and you should be able to correct it.

This blog article series is produced in collaboration with John Dolan, best known as one of the world’s foremost HPLC troubleshooting authorities. He is also known for his research with Lloyd Snyder, which resulted in more than 100 technical publications and three books. If you have any questions about this article send them to TechTips@sepscience.com